About Black Ash Baskets

The Basket Maker's Tree

Processing wood into fine weaving materials is a time consuming endeavor. For Eric’s baskets, it all starts with the Black Ash tree. Black Ash is unique among all trees in North America in that it does not have fibers connecting the growth rings to each other. This is essential for basket making and often referred to as the basket maker’s tree.

By pounding the length of a black ash log, the spring wood is crushed, allowing the summer wood to be peeled off in long strips. These long strips are split in half, in a process called ‘splitting to satin.’ Next, these strips are sanded or scraped clean. The final step is to pull these strips through a bank of knives making them uniform in width. These pieces are now ready to be woven with.

Some Numbers

to Ponder...

Ash Trees so far have been lost

from the Emerald Ash Borer

Estimate of Eric’s baskets

from a single tree

Years for a Black Ash tree

to fully mature

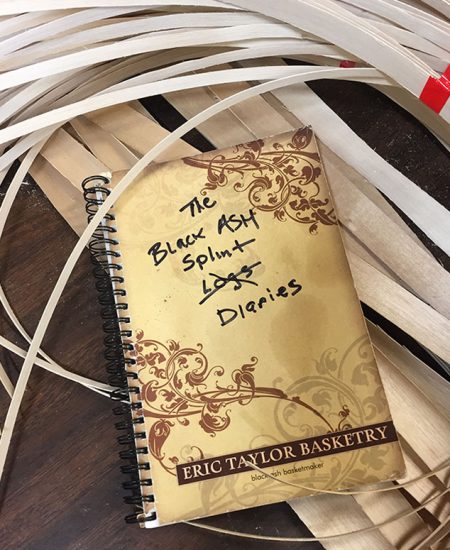

Photos show Eric processing trees in Wisconsin—starting from picking out the tree to splitting of the wood to the hard pounding—to produce splint .

Some Black Ash Facts

- The Emerald Ash Borer (EAB) is from Asia

- It's believed to have arrived via infested wood crates

- First identified in Detroit, Michigan in 2002

- Visually, the EAB is a quite beautiful insect

- Estimated loss is more than $280 billion

- In the U.S. we do not have the wasps that kill EAB's in China

- Blue Ash trees are seemingly resistant to EAB

- Federal Agencies are working hard to find an insecticide

Eric's Cottage Baskets

Processing wood into fine weaving materials is a time consuming endeavor. For Eric’s baskets, it all starts with the Black Ash tree. Black Ash is unique among all trees in North America in that it does not have fibers connecting the growth rings to each other. This is essential for basket making and often referred to as the basket maker’s tree.

By pounding the length of a black ash log, the spring wood is crushed, allowing the summer wood to be peeled off in long strips. These long strips are split in half, in a process called ‘splitting to satin.’ Next, these strips are sanded or scraped clean. The final step is to pull these strips through a bank of knives making them uniform in width. These pieces are now ready to be woven with.

Mold Making

Every element of one of Eric’s baskets is made using a molded system to insure complete symmetry. Before the weaving process begins, various molds are made for a single basket; a body mold, two rim molds and a handle mold.

Body

First, wood is cut into pieces, then glued and pressed into blocks and finally shaped into the forms needed by using sanders, lathes and other tools.

Rims & Handles

Steam bending, or boiling wood, is a process that allows hardwoods to be shaped and fitted around the forms, creating pieces that are used to develop the skeleton of the basket. Bending wood into handle and rims involves years of experience in wood preparation and bending knowledge. It begins by carefully selecting wood with straight grain and ripping it into smaller strips. These strips are then ready to be boiled or steamed until pliable and quickly bended around forms where they are left to thoroughly dry.

“There's more coming here”